- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

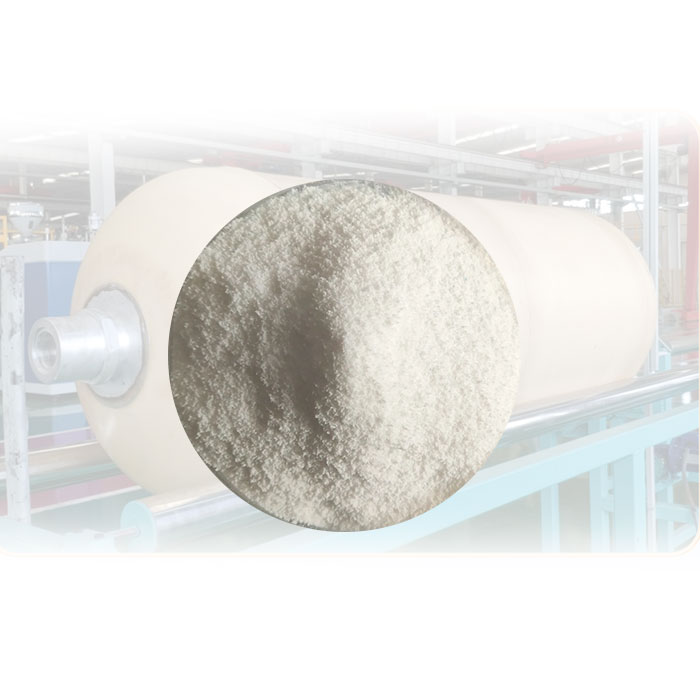

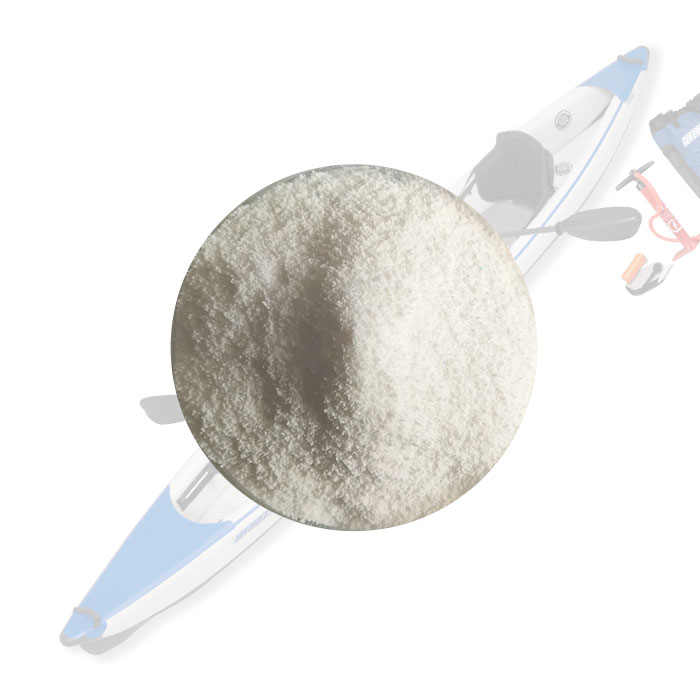

Rotomolding LLDPE

Rotomolding LLDPE

Rotomolding LLDPE is a non-toxic, odorless, and milky white particle with a density of 0.918-0.935g/cm3. Compared with LDPE, it has higher softening and melting temperatures, and has advantages such as high strength, toughness, rigidity, heat resistance, and cold resistance. It also has good resistance to environmental stress cracking, impact strength, tear strength, and can withstand acid, alkali, organic solvents, etc. It is widely used in industries, agriculture, medicine, health, and daily necessities.

What are the application areas of Rotomolding LLDPE?

Rotomolding LLDPE has penetrated into most traditional markets of polyethylene, including films, molds, pipes, and wires and cables. Anti leakage plastic film is a newly developed LLDPE market. Geomembrane, a large extruded sheet material used as a waste landfill and waste pool liner to prevent leakage or pollution of surrounding areas.

Some of LLDPE's film markets, such as production bags, garbage bags, elastic packaging, industrial liners, towel liners, and shopping bags, utilize the advantages of this resin after improving strength and toughness. Transparent film. The penetration resistance and stiffness of LDPE film do not significantly affect the transparency of the film. Injection molding and roll molding are the two largest molding applications of LLDPE. The superior toughness, low temperature, and impact strength of this resin are theoretically suitable for waste bins, toys, and refrigerated appliances. In addition, LLDPE's high resistance to environmental stress cracking makes it suitable for injection molded lids in contact with oily foods, roll forming waste containers, fuel tanks, and chemical tanks. The market for application in pipe and wire and cable coatings is relatively small, where LLDPE's high fracture strength and resistance to environmental stress cracking can meet the requirements. 65% to 70% of LLDPE is used for making thin films.

The LLDPE polymer generated during the copolymerization process has a narrower molecular weight distribution than general LDPE, and its linear structure gives it different rheological properties. The melt flow characteristics of LLDPE meet the requirements of new processes, especially with the use of thin film extrusion technology, which can produce high-quality LLDPE products. LLDPE is applied to all traditional markets of polyethylene, enhancing its resistance to elongation, penetration, impact, and tear. Its excellent resistance to environmental stress cracking, low temperature impact, and warping make LLDPE attractive for pipe, sheet extrusion, and all molding applications. The latest application of LLDPE is as a lining layer for waste landfill and waste liquid tank as a plastic film.

Rotomolding HDPE

Rotomolding HDPE

Rotomolding PP

Rotomolding PP

As a professional Rotomolding PP manufacture, you can rest assured to buy Rotomolding PP from our factory and Rotoun will offer you the best after-sale service and timely delivery.

The following is an introduction to Rotomolding PP Rotoun hope to help you better understand Rotomolding PP. Welcome new and old customers to continue to cooperate with us to create a better future together!

Rotomolding PA

Rotomolding PA

As a professional Rotomolding PA manufacture, you can rest assured to buy Rotomolding PA from our factory and Rotoun will offer you the best after-sale service and timely delivery.

The following is an introduction to Rotomolding PA, Rotoun hope to help you better understand Rotomolding PA. Welcome new and old customers to continue to cooperate with us to create a better future together!

Featured Products

About Us

Established in 2013, registered capital of 12.5 million. Rotoun has domestic advanced powder processing technology, a complete set of polymer measuring instruments, complete certification certificates( NSF, UL, ROHS, etc) and an annual production capacity of more than 21000 tons.

Main products LLDPE, HDPE, XHPE, PP, PA for many applications.

More Material For Different Applications

-

GREAT VARIETY

GREAT VARIETY

Wide variety of products,complete specifications

View Details -

TEAM

TEAM

We have our own R&D team and hvae applied for a number of patents

View Details -

EQUIPMENT

EQUIPMENT

Company has a lot of advanced production equipment.

View Details -

QUALITY

QUALITY

Our company makes the product quality always put in the first place

View Details -

TIME

TIME

We will deliver the goods on time within the promised time after placing the order.

View Details

New Products

News

Firefighting practical exercises are conducted in enterprises to build a strong safety firewall

On April 9, 2025, the Shengshan Town Fire Brigade entered our company to conduct an immersive fire drill, where professional instructors taught fire extinguisher operation and emergency evacuation skills step by step. Safety is no small matter, prevent it before it ignites!

Our company participates in the 2025 China Plastics Association Rolling Plastic Special Committee Annual Meeting

On May 16, 2025, our company participated in the "China Plastics Association Rolling Plastic Special Committee 2025 Annual Meeting" held in Xingtai, Hebei Province.

A high-temperature resistant cross-linked coating material

We all know that ordinary PE materials have excellent acid and alkali corrosion resistance, but they cannot withstand very high temperatures. However, customers have an increasing demand for high-temperature coating materials, especially in the application of high-temperature chemical liquids and high-temperature slurry transportation.

New member of domestic rotational molding materials - "R442U" makes a brilliant debut

Many domestic rotational molding product companies have always relied on a certain rotational molding material from Thailand to meet their requirements for good whiteness and minimal deformation of their products, without any further options.

ARMO 2023 Poland Annual Conference Video Sharing - ROTO EVOLUTION Innovative Equipment

In the previous episodes, our company's manager Mr. Wang shared the content about the current situation and trends of the European injection molding industry at the ARMO annual meeting.

From Knowledge to Action: Our Fire Extinguisher Training in Practice

Fire safety is no trivial matter; preventing fires before they start is crucial. To enhance the fire safety awareness of all staff and improve their emergency self-rescue capabilities, today, our company organized a Fire safety training activity with the theme of "Knowledge Popularization and Practical Operation of Fire Extinguishers".