- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

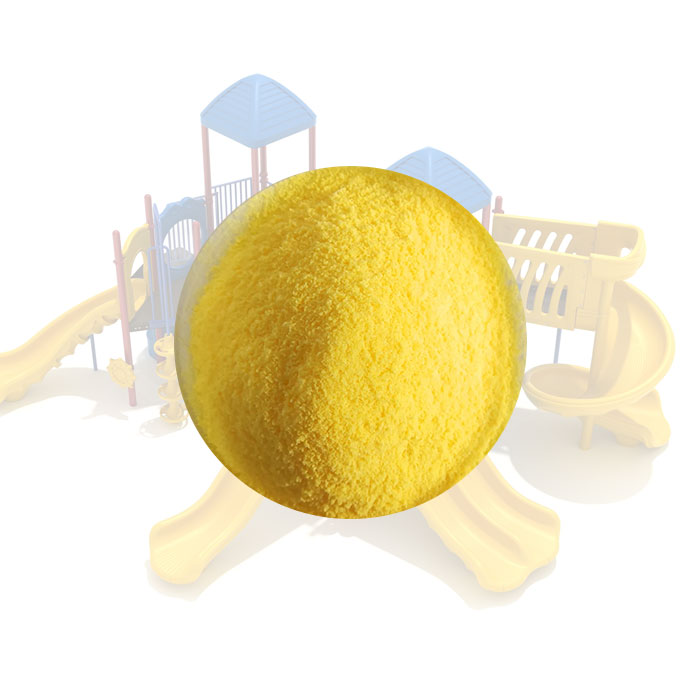

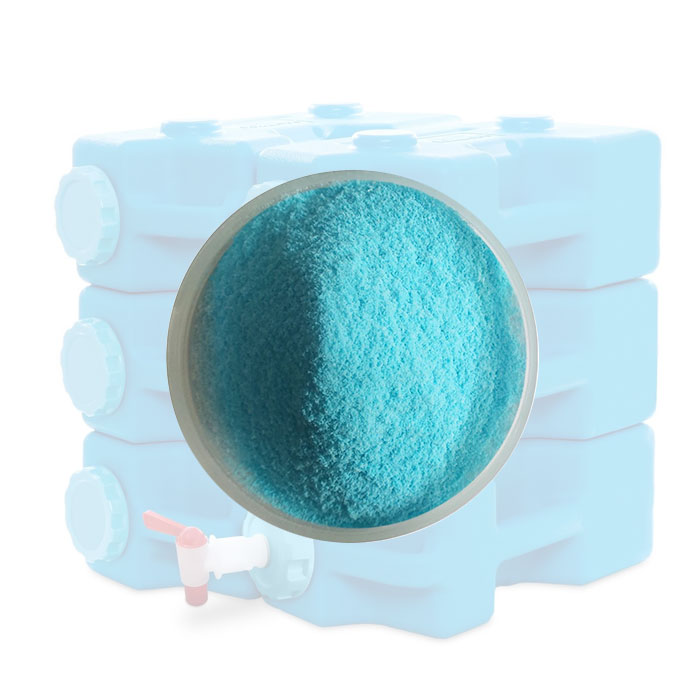

Rotational Moulding Material LLDPE C6 PE Plastic

Rotational Moulding Material LLDPE C6 PE Plastic, LLD115P is a hexene copolymer modified rotational moulding material, with UV20 performance, was designed for outdoor long term application. Providing customized colors, also can be require to add dust proof, mildew proof and antibacterial function.

Model:LLD115P

Send Inquiry

Product Description

Rotational Moulding Material LLDPE C6 PE Plastic, LLD115P is a hexene copolymer modified rotational moulding material, with UV20 performance, was designed for outdoor long term application. Providing customized colors, also can be require to add dust proof, mildew proof and antibacterial function.

|

Material State |

● Commercial:active |

|

Material Availability |

● Asia |

|

Additive |

●Heat Stabilizer ●UV Stabilizer ●Mould Release agent |

|

Features |

●High strength ●High weatherability |

|

Application |

●Tank, Playground Recreation, Outdoor Products. |

|

Regulations |

●ROHS ●FDA ●AS4766 |

|

Packaging |

● 20Kg / packaging |

|

Shelf Life |

●One year from the date of production |

| Datasheet | Typical Values | Unit | Test Method |

| ● Physical Properties | |||

| Density | 0.936 | g/cm3 | ISO 1183 |

| Bulk Density | 0.350 | g/cm3 | ISO60 |

| Melt Index (190℃,2.16Kg) | 5.0 | g/lOmin | ISO1133 |

| Dry Flow Rote | 22 | s/lOOg | ARM |

| E.S.C.R. | 1000 | h | ASTM DI 693 |

| Melting Point | 126 | ℃ | ISO 11357 |

| ● Mechanical Properties | |||

| Tensile Strength ot Break | 18 | MPa | ISO527 |

| Tensile 日ongction ot Break | 800 | % | ISO527 |

| Flexural Modulus | 700 | MPo | ISO 178 |

| impact Strength | 28 | J/mm | ARM |

| Hardness, Shore D Thermal Properties | 62 | D | ISO868 |

| Deflection Temperature(0.45MPa) | 59 | ℃ | ISO75 |

| Vicat Softening Point | 118 | ℃ | ISO306 |

| Brittleness Temperature | -70 | ℃ | ISO974 |

| ● Aging Properties | |||

| Oxidation Induction Time | 80 | min | ISO11357 |

| UV Rating | 20000 | h | ASTM 2565 |

| ● Other Function | |||

| Surface Resistivity | 1017 | IEC60093 | |

| Flame Class | HB | Grade | UL-94 |

This guide data is typical of the brand product data, and can not be used as indicators of supplier quality assurance.。

Hot Tags: Rotational Moulding Material LLDPE C6 PE Plastic, China, Manufacturer, Supplier, Factory, Wholesale

Related Category

Send Inquiry

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.

Related Products